Company specialized in 3D laser engraving, 3D printing of technical parts and laser welding.

LASER welding: the most advanced technology

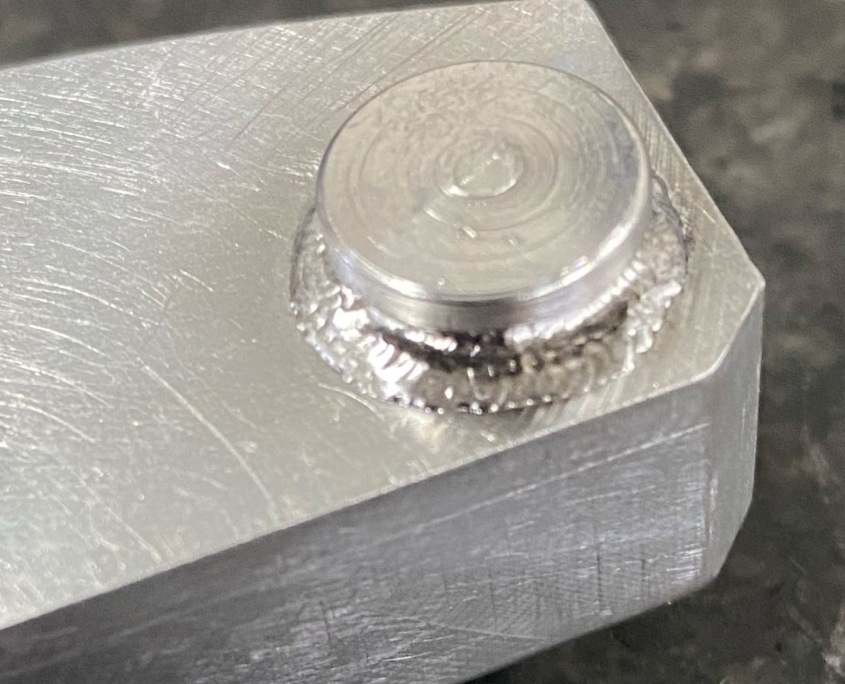

CUSTOM3D offers the welding service using the most advanced technology such as LASER welding and using more classic systems such as MICROPLASMA and TIG welding also. The most appropriate technique is applied as appropriate.

We specialize in the welding of moulds, dies, medical parts (surgical material, prostheses, etc.) and in general special mechanical parts, making contributions of great precision and quality.

The laser welding system is based on the fusion of the material by means of the energy provided by a beam of laser light in a temporal space between pulses of approximately 1 µs (microsecond).

Advantages over other welding systems:

- Allows the contribution of material with an accuracy of tenths of a millimetre

- Welding is performed “cold”, at room temperature, the piece does not have to be heated

- Deformation are avoided

Laser welding technique provides maximum accuracy and warranty.